Plain Weave – Simple, straight forward constructions in fabric thread arrangement

Fabrics are very much part of our daily life, from deciding what we will be wearing at different times of the day, to the occasion wear and the sensations for those exclusive parties, not to mention the uniform if we have one, or about buying the new one spotted last Tuesday while passing by a store window.

Yes! Fabrics mean so much to us, that unconsciously we would be spending considerable time on musing over the colors, designs, the comfort we require and what not for the wear.

So about what is so important to us, have we stopped to think, what goes into their making, and how the raw material gets processed into the fine clothing that we put on?

Let us peer into that world and familiarize ourselves with the basics.

Weaving

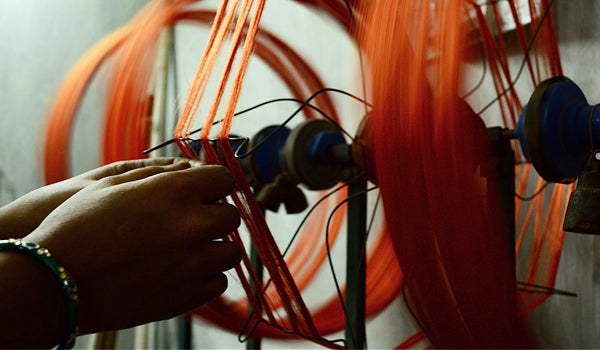

Weaving is the production of fabric by interlacing two sets of yarns so that they cross each other, normally at right angles, usually accomplished with a handloom or power-operated loom.

In weaving, lengthwise yarns are called warp; crosswise yarns are called weft, or filling. Most woven fabrics are made with their outer edges finished in a manner that avoids raveling; these are called selvages. They run lengthwise, parallel to the warp yarns.

- The manner in which the yarns are interlaced determines the type of weave.

- The yarn count and number of warp and filling yarns to the square inch determine the closeness or looseness of a weave.

- Woven fabrics may also be varied by the proportion of warp yarns to filling yarns. Some effects are achieved by the selection of yarns or of combinations of yarns.

The three types of weave

Plain Weave – Plain weave is the most basic of the three types. When weaving plain weave, the warp and weft are aligned which forms a simple criss-cross pattern. Each weft thread crosses the warp threads by going alternately, first over one warp, then under the next and so on. The next weft goes under the warp that the neighboring weft went over, and again so on.

Twill - A type of textile weave that has a pattern of diagonal parallel ribs. This technique is done when the weft thread crosses over one or more warp threads and then under two or more warp threads and so on. Next weft does the same but some warps later so it creates the characteristic diagonal pattern. Twill has different front and back sides which are called “technical face” and “technical back”.

Satin - A weave that typically has a glossy surface and a dull back. It is a warp-faced weaving technique in which warp yarns are "floated" over weft yarns, which means that warp goes over much more wefts than in twill which makes its surface very soft.

For the moment let us concentrate on the Plain Weave.

The Plain Weave

- The Plain weave that is also called Tabby Weave is the simplest and most common of the three basic textile weaves. Made by passing each filling (weft) yarn over and under each warp yarn, with each row alternating, a lot of intersections are produced. Since the warp and weft threads cross at right angles, they are aligned to form a simple criss-cross pattern.

- Plain-weave fabrics that are not printed or given a surface finish have no right or wrong side. They do not ravel easily but tend to wrinkle and have less absorbency than other weaves.

- The visual effect of plain weave may be varied by combining yarns of different origins, thickness, texture, twist, or colour. Fabrics range in weight from sheer to heavy and include such types as organdy, muslin, taffeta, shantung, canvas, and tweed.

- Examples of fabrics made in plain weave include muslin and taffeta.

- Some plain weaves have ribbed effects in them e.g. bengaline, and are produced by employing heavier yarns for either the warp or the filling.

- In the basket weave, an example of the plain weave, one or more filling yarns are passed alternately over and under two or more warp yarns, as seen in monk’s cloth.

- The plain weave is essentially strong and hard-wearing, and is used for fashion and furnishing fabrics.

Weaving the Plain Weave

Weaving the Plain Weave

- The Plain weave requires only two harnesses and has two warp and weft yarns in each weave unit. To produce it, the warp yarns are held parallel under tension while a crosswise weft yarn is shot over and under alternate warps across the width of the web. The weave unit is completed at the end of the second row, when the weft has been inserted over and under the opposite set of warps, thus locking the previous weft in place.

- Fabric length is increased with the insertion of each succeeding weft yarn. When warp and weft yarns are approximately equal in size and quantity, the finished fabric is balanced and potentially stronger than cloth made of the same kind and number of warp and weft yarns in any other basic weave.

- Tabby woven with different-sized warp and weft yarns results in such fabrics as taffeta and poplin, in which many fine warps are interlaced with proportionately fewer thick weft yarns to form cloths with crosswise ridges or ribs.

- The term extended tabbydescribes any weave in which two or more warps or wefts, or both, are interlaced as a unit. The group includes fabrics with basketry effects and fabrics with ribs formed by groups of warps or wefts in each shed.

- Tapestry weave is a tabby in which a variety of coloured weft yarns are interlaced with the warp to form patterns. It is usually an unbalanced weave, with wefts completely covering a proportionately low number of warps. These cloths are sturdy and compact. Although they are flat and generally do not drape well, they have been used for centuries to make ceremonial and decorative dress and costumes.

The Types of Plain Weaves

- Balanced plain weavesare fabrics in which the warp and weft are made of threads of the same weight (size) and the same number of ends per inch as picks per inch.

- Basket weaveis a variation of plain weave in which two or more threads are bundled and then woven as one in the warp or weft, or both.

- A balanced plain weave can be identified by its checkerboard-like appearance. It is also known as one-up-one-down weave or over and under pattern. Examples of fabric with plain weave are chiffon, organza, percale and taffeta.

End uses

Plain Weaves have a host of end uses that range from heavy and coarse canvas and blankets made of thick yarns to the lightest and finest cambric and muslins made in extremely fine yarns. The Plain weave also finds extensive use in the making of blankets, canvas, dhothis, sarees, shirting, suiting, etc.

The plain weave has the following characteristics:

- It has the maximum number of binding points

- The threads interlace on an alternate order of 1 up and 1 down.

- The thread density is limited

- Cloth thickness and mass per unit area are limited.

- It produces a relatively stronger fabric that is obtained by any other simple combination of threads, excepting that of “gauze” or “cross weaving”.

Textural Stability of Plain Weaves

- The firmness of any woven structure depends on the frequency of interlacing between the warp and weft threads. The greater the number of intersections the better will be the firmness of the cloth.

- Let us consider the case of two fabrics woven with identical warp and weft counts and thread settings. Consider that one is woven as plain weave and the other with any other weave such as twill, sateen etc.

- It will be seen that the latter will be less firm, and therefore of weaker texture than the former, because the threads composing it would be bent in a lesser degree than those of the plain weave, thereby causing them to be less firmly compacted. Thus it is important that the counts of warp and weft, the number of warp threads and picks per inch, and the weave, should be properly proportioned, in order to obtain the best results.

The range of Textures in Plain Weaves

The plain weave is produced in a variety of forms and textures, possessing totally different characteristics, which adapt it for specific purposes.

A variety of forms in textures are produced:

- By causing a differential tension between the warp threads during weaving,

- By using various counts of yarn for weaving different types of fabrics,

- By using warp and weft yarns of different counts in the same fabric.

The term ‘texture’ is related to the type of material, counts of yarn, the relative density of threads, weight, bulk, feel during handle, and other properties. The range of textures produced in plain cloth is wide. An ideal plain cloth is one which has identical or similar warp and weft constructional parameters.

Modifications of Plain Weave

- The plain weave may be modified by extending it warp or weft way or both. The extension of the plain weave thus produces a rib effect. A warp rib results from extending the plain weave in the warp direction and a weft rib structure results from extending the plain weave in the weft direction. A matt rib results from extending the plain weave in both directions.

Warp Rib Weaves

- These are produced by extending the plain weave in warp wary direction. The warp rib weaves are constructed both on the regular and irregular basis.

Weft Rib Weaves

Weft Rib Weaves

- These are constructed by extending the plain weave in the weft direction in both the warp and weft rib weaves. The appearance of the cloth depends on the respective thread settings, and to achieve good effects, it is necessary to weave a weft rib with a high number of picks per inch and a comparatively low number of ends per inch.

- Similarly, the warp rib effect can be enhanced with a high number of ends per inch and a comparatively low number of picks per inch. The prominence of the rib can be increased by suitable use of coarse and fine yarns. The dependence of all rib constructions upon the correct thread settings is marked.

Uses of Rib Weaves

Uses of Rib Weaves

Rib weaves are used in gross grain cloths, matelasse fabrics, repp cloth which is extensively employed for window blinds in railway carriages and other vehicles, upholstering furniture, and cambric pocket handkerchief.

Matt Rib Weaves

These weaves are also variously known as hopsack or basket weaves. The matt rib structures result from extending the plain weave in both directions.

In case of regular matt weave, the plain weaves are extended equally in the warp and weft directions, whereas in case of irregular matt weaves, the plain weave is extended unevenly or irregularly in the warp and weft directions.

Uses of Matt Rib Weaves

Uses of Matt Rib Weaves

- Matt weave finds extensive uses for a great variety of fabrics such as dress materials, shirting, sailcloth, duck cloth etc.

- The plain weave furthermore known as “calico” or “tabby” weave is the simplest of all weaves. The array of relevance of this weave is wide. The threads interlace on alternating order of 1 up and 1 down.

- The code involved in the making or construction of a basic plain cloth is the interlacement of two continuous threads or the weavers lingo calls them warp (vertical yarn) or weft (horizontal yarn) in an opposite approach to each other, with every thread in each series passing alternately below and above consecutive threads forming a simple criss - cross pattern. Hence through such interlacement plan every warp interlaces with every thread to its maximum limit, thus producing a firm texture of cloth.

Rib Weave

- Rib is a variant of the Plain weave. It is created very correspondingly to a plain weave. The basic construction follows the same pattern, modified by extending it warp or weft way or both The dissimilarity can also be that Rib weave uses one heavyweight yarn.

- This is used for either the warp of weft yarns and the end result is a fabric that has raised ribs either horizontally or vertically down the fabric, depending on whether the heavier, thicker yarn is used for the warp or the weft. Multiple variations of Ribs are Warp Rib, Weft Rib & Plain Rib.

Matt or Basket Weave

Matt or Basket Weave

- Basket is again a variant of the plain weave. It follows the same pattern of the weft going under one warp yarn and over the next, creating a checkerboard effect.(See figure)

The matt rib structures result from extending the plain weave in both directions.

- The difference between the two is that adjacent yarns are grouped together. They are usually grouped in pairs, but sometimes more yarns can be grouped together. These are woven as if they are one yarn. This results in a fabric that resembles a woven basket; this is where the name originates.

- In case of regular matt weave, the plain weaves are extended equally in the warp and weft directions, where as in case of irregular matt weaves, the plain weave is extended unevenly or irregularly in the warp and weft directions.

End Uses:

- Plain weaves have far-reaching uses and are used in cambric, muslin, blanket, canvas, dhothi, saree, shirting, suiting, etc.

- Rib weaves find utility in gross grain cloths, matelasse fabrics, repp cloth which is extensively employed for window blinds in railway carriages and other vehicles, upholstering furniture, and cambric picket handkerchief.

Normal/Plain Weave

Plain Weave Manufacture

- Plain Weave is one of the most fundamental fabric weaves available. Most other types of weave are just variations of the plain weave. Plain weave is created using warp threads and a weft thread. The warp threads are spaced out evenly and held down at either end by a loom. The weft yarn is then interwoven between these warp yarns. The weave pattern for plain weave is ‘One under one over.’ This means that the weft goes over one warp yarn and under the next. This repeats until the whole fabric is done.

- Plain weave can be recognized by its checkerboard effect. This is usually a balanced weave which means that yarns of the same weight, not necessarily the same yarns are used for both the warp and weft, creating a fabric with a uniform appearance and the same properties in the warp and weft yarns. Plain weave can be woven with different colours to create colour woven fabrics, such as striped fabrics and they can be printed or have other finishes applied to them.

- Plain weave fabrics can be anything form heavyweight to sheer, depending on the types of yarns used and the tightness of the weave. Examples of fabrics made using a plain weave a Taffeta, Organza, Chiffon, Canvas, Tweed and Muslim. All of these fabrics are very different in terms of weight and appearance but are all made using the same weave.

Properties of Plain Weave Fabrics

- No right or wrong side

- No lengthwise of crosswise stretch, only stretch is on the bias

- Doesn’t fray as easily as other weaves

- Creases easily

- Less absorbent than other weaves

- Fabrics range in weight from sheer to heavy, depending on the yarns used

- Versatile

- Flexible

- Tightest weave structure

- Strong

- Hard-wearing

- Durable

End Uses of Plain Weave Fabrics

- Shirting

- Suiting

- Outer garments

- Toiles in the case of Calico fabric

- Sheer fabrics

- Blouses

- Dresses

- Garments that do not require much stretch

Simple Variations

- The continuing popularity of plain weave is due to its simplicity as well as to the many possible variations in color, texture, and yarn count.

- Plain weave is the least expensive fabric to produce. At the same time, weavers often purposefully use this pattern to avoid visual competition with other aspects of the cloth: textured fibers (such as linen and silk dupioni); novelty yarns (such as tweed, chenille, and bouclé); printed patterns (on fabrics such as calico and chintz); and dyed patterns (on fabrics such as batik, ikat, and tie-dye). Textiles that have a specialty finish, including flannel (napped), organdy (parchmentized), ciré and moiré taffeta (embossed), are also frequently plain weaves.

- Georgette, chiffon, and voile (sheer fabrics that are used for scarves, bridal veils, and decorative overlays on full skirts and dresses) are plain weave fabrics made with tiny, highly twisted silk or manufactured yarns. The twisted yarns create minute spaces in the fabric allowing light or another color to show through. Softer fabrics used for dresses and skirts, such as cotton lawn and rayon challis, are made with yarns that have a very light twist. This helps make the surface of the finished cloth feel very smooth. China silk, a popular fabric for women's blouses, is a fine cloth with a high yarn count (large number of threads per inch). Buckram and crinoline, plain weave fabrics with a low yarn count, are used as stiff linings in the construction of elaborate hats and dresses. Muslin is a cheap, medium-weight plain weave fabric that is often used by tailors and designers to make a test garment before working with more expensive material.

- Striped and plaid fabrics, such as tartan, madras, and gingham, are made by changing the color on sections of filling and/or warp yarns. Gingham, for example, usually has thin stripes of red and white or blue and white threads in the warp and identical stripes in the filling. In the finished cloth the stripes create a checkerboard pattern. This look can be imitated by printing the same pattern on a plain weave fabric. Chambray, a popular cloth for button-down shirts, is made with filling yarns that are one color (frequently white) and warp yarns that are a different color. When the filling and warp have a high color contrast, the overall fabric seems to shift color as it moves on the body. This is known as iridescence. Ikat fabrics have a multicolored warp that is dyed before the weaving process begins. When the weaver uses plain weave and a neutral-colored filling yarn, the color and pattern of the warp yarns are allowed to stand out. A similar technique is used to produce fabrics such as tweed and chenille, where the goal is to highlight the texture of the novelty yarn. These bulky or fluffy yarns are usually in the filling. Simply using fewer yarns per inch in the warp and vice versa can also emphasize filling yarns.

- Medium-weight plain weave fabrics are sometimes called "print cloth" because they're often used for printed fabrics such as chintz and calico. The smooth surface of plain weave is excellent for printing. These fabrics are also low-cost, which balances out the expense of printing a textile. One drawback to plain weave, however, is that other structures such as twill weave and double weave are much stronger. Plain weave fabrics are best used for clothing and household furnishings that do not take much abuse (such as curtains) or are periodically replaced (such as underwear and bedsheets).

Rib and Basket Weave

- Changing the size or number of certain filling and/or warp yarns allows the creation of other variations of the plain weave. When several yarns are grouped together or larger yarns are used, a straight raised ridge called a rib or cord is formed.

- Poplin is a cotton or polyester fabric with very tiny ribs in the filling direction. This added thickness makes the cloth very crisp. Taffeta and faille, made of silk or a synthetic material such as acetate, are crisp fabrics with a slightly larger rib. Taffeta is often used to make ball gowns because the ribs make an elegant swishing sound when the fabric rubs together. Gros-grain ribbon is another fancy material with ridges in the filling direction. Bedford cord is a heavy fabric made as a lengthwise ribbed weave that resembles corduroy and is used for pants. Rip-stop nylon is a very strong fabric with noticeable ribs in both the filling and the warp direction. In this case, the ribs help prevent the fabric from tearing. Rip-stop is often used for sports gear such as windbreakers and athletic shoes.

- Basket weave fabrics are made by having one or more filling yarns go over, under, over, … more than one warp yarn at a time. This can be used to create a fabric that has a better drape and luster than standard plain weave, but the exposed yarns are more likely to be snagged. Oxford cloth, a popular fabric for men's dress shirts, is a basket weave that has one filling yarn going under and over two warp yarns at a time. Heavier basket weaves, such as canvas and sailcloth, have been used for shoes and outdoor clothing such as jackets and overalls for construction workers, sailors, and hunters. Monk's cloth, a very soft basket weave fabric that is easily damaged, has four yarns running together in both the filling and the warp direction.

Plain-weave fabrics

Some of the plain woven fabrics are available in the market under the following names.

- Sheeting

- Lawn

- Muslin

- Poplin

- Canvas

- Casement

- Organdy

- Cambric

- Chambray

- Gingham

- Voile

- Georgette

- Chiffon

- Rubia

All these fabrics are different from each other because of variations in thickness, colour or twist of yarn in warp and weft of both. The plain weaves that we are going to touch upon today are mostly in cotton.

- Sheeting is medium to heavy weight plain weave fabric. It is mostly used for upholstery, bed covers etc. Fine sheetings are woven with cotton- polyester blended yarns.

- Lawn is a light, thin fabric, made slightly stiff and crease-resistant by finishing. It is used in making dresses, blouses and handkerchiefs. It has typically 30 × 32 ends/picks per cm.

- Muslin is light weight to medium weight stiff, unbleached and unfinished plain woven cloth. It is used in making designer sample garments. Finished muslins are used in sheets, furnishing etc. Besides cotton, they may be made of silk and worsted yarns also.

- Poplin is a medium plain weave fabric having finer warp and thick weft. Its main characteristic is that it looks like having rib effect in the weft direction. A considerable amount of mercerized cotton goes in making poplins. All poplins are finished and calendared (pressed). It is used in making petticoats, pyjamas, blouses etc. Typically the number of ends and picks is 48/24 per cm.

- Canvas is a heavy weight densely woven plain grey (unfinished) fabric. It is used in making working cloth, jump suits and industrial clothes. Besides cotton, hemp and jute fibres are also used. Ends/picks: 10-20/10-16 per cm.

- Casement is a plain weave cloth with lesser twist in warp and weft. It is used in making furnishing, embroidery work, table linen etc. Ends/picks 21 × 25 per cm.

- Organdie is a light weight, crisp, sheer, shining white cotton fabric, which is produced by using fine (thin) warp and weft yarn. It is given a special chemical finish. It is used in making dress materials.

- Cambric is a soft, smooth closely woven (compact) fabric, which is given a finish on the upper surface of the fabric to give a glazed (shining) effect. It is used in making dress materials, children’s dresses, table linen etc. Typically it has 38 ends/cm. and 32 picks/cm.

- Chambray is a plain, medium to heavy weight, woven fabric with coloured warp and white weft. It can be in plain, strips or check designs. It is used in making, work suits, overalls, men’s suits etc. (Denim comes under this, except for the weave).

- Gingham is a medium to light weight plain weave fabric of open texture having different coloured warps and wefts. They vary in qualities according to the yarn used, fastness of colour, weaves and weight. They are used for making house dresses, aprons, curtains etc.

- Georgette is a sheer light-weight fabric with double yarn, highly twisted in S and Z directions, in warp and weft. It gives a sand-like rough appearance on the surface of the fabric. It is used in making saris and women’s wears.

- Voile is sheer light-weight fabric, highly twisted, using double fine combed yarn in warp and weft. This gives a crisp body and good draping quality. It is used in making blouses, bedspreads, summer dresses, children’s wear etc. Besides cotton, voile is made from worsted also.

- Rubia highly twisted, using double fine yarn warp and weft fabric, plain textured (appearance) which gives a transparent look. It is used in making sareess and blouses.