Chintakindi Mallesham – Padma Shree awardee gets biopic showcasing his invention and life

A recent announcement about the biopic of Padmashree awardee Chintakindi Mallesham being on the cinema floors already is heartening news indeed. Showcasing a son’s love for his mother, whose path-breaking effort led to an invention that earned him the fourth highest civilian award of the land, the Telugu language film is already contemplated, the cast chosen and the movie in the process of shooting. Directed by debutant Raj, it figures Telugu actor Priyadarshi playing the role of Mallesham while actress Jhansi shall be playing the role of his mother. The storyline sketches the ten important years of a school drop-out, who could not bear to see his weaver mother suffer while winding yarn for the subsequent weaving process in the making of the famed Pochampally Ikat saree. By sheer dint of hard work he was able to invent a machine that mechanized the spinning and reduced the overall time in the making of the Pochampally saree drastically. This invention not only made the life of his mother easier but also that of all the other women active in the ASU spinning process necessary for the making of the Pocahampally saree.

What is the Asu process?

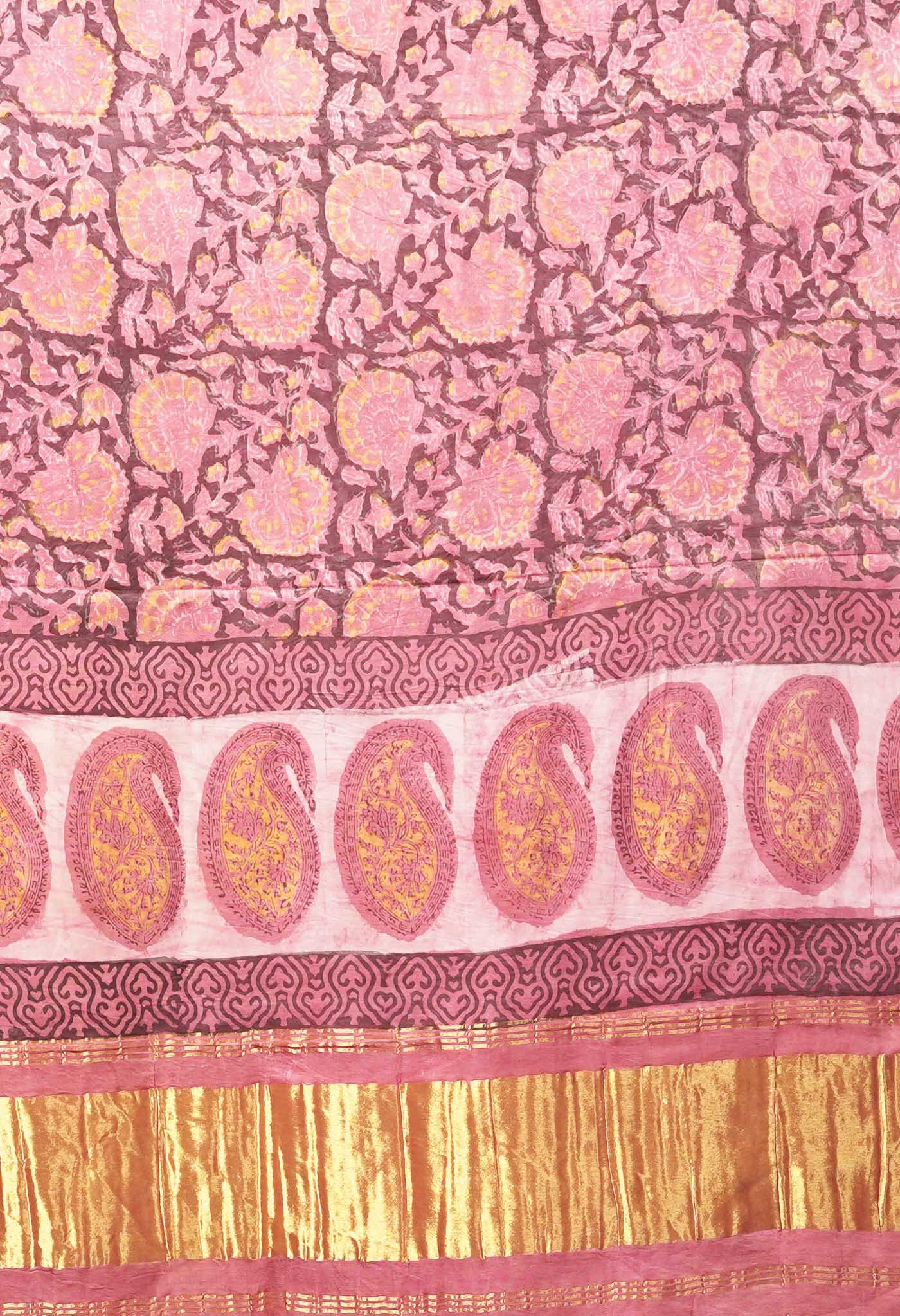

Usually, the process of making a tie and dye' silk saree in Pochampally tradition begins with the selection of silk thread. A hand winding process called Asu is required in the making of the traditional ‘Tie & Dye’ Pochampalli silk saree. The weaver has to stretch her arms continuously to wind yarn around two sets of pegs on either end of a four-foot structure before the saree is woven. That involves moving the hand manually over a space of one meter up and down around semi-circularly arranged pegs 9000 times for one saree.

Using the process of Asu, a triangular shape is given to the threads and designs are drawn on this shape. Tying is done where required as per the design and the threads are then dyed in selected colours. Once dried and untied, the dyed silk threads are rolled into spindles. The spindles are used appropriately in looms and the saree is woven.

Besides incurring terrible pain at the elbows and joints while doing so, it also took a weaver about six hours in the completion of a saree.

Where there is a will there is a way

When Mallesham saw his mother Laxmi, a weaver by profession, in doing the ASU spinning process get tremendous pain in her shoulders & elbow joints he developed a strong desire to relieve his mother’s pain and urged him to seek a solution soon. Part by part he developed and fitted mechanical devices to a wooden frame.

He had had no formal education and many a time his trial and error efforts caused wastage and a drain on his precious hard earned money. But he did not lose heart. Commuting from his village to nearby cosmopolitan capital city Hyderabad, he shopped for relevant components. Having good observational skills he was able to complete some portions of the so-called machine successfully. Many within his relatives try to dissuade him and his seemingly wasting ways with their nasty comments, so he came to Hyderabad to eke out a living and also get a solution for his incomplete machine.

It is said that God helps who help themselves and so his machine was almost ready except for an important movement necessary for its success. He reached a snag where he had no idea which part to use for the action that involves the thread to go round the peg and slide down the last thread perfectly. After an almost nine year struggle, in Feb.1999, when he working in a machine shop in Balanagar, Secunderabad, in one particular machine he noticed a movement similar to what he required.

His excitement knew no bounds. He took leave rushed to a workshop to get that component manufactured. The machine worked. Success was his at last! His friend used the ASU machine to process the yarn and make a saree. The quality of the saree turned out to be much better than the one made involving the hand woven ASU process. His was an unexpected improvisation that was a bonus to the find.

The first machine was made in 1999, mounted on a wooden frame. The next year, the wooden frame was replaced by a steel one. Subsequently many electronic components have been added over the years thereby increasing the functionality and flexibility of the design.

The Asu machine has actually reduced the time taken to weave a saree from 4 hours to just 1.5 hours. The productivity has increased three times. Women who were always involved in the spinning activity could now be pain-free and best of all earnings for them have risen well since then.

Earning the Padmashree award

When Chintakindi Mallesham introduced his invention for the speeding up of the ASU process, he reduced the drudgery and the insufferable elbow and joints pain that resulted from the spinning process. Despite being a school dropout, he did not lose heart and surmounted the difficulties from the lack of a formal education with his ingenuity and unusual thinking. The invention saved the time-taken for making one saree from six to one and a half hours, did away with the inhuman drudgery of manually winding yarn nine thousand times around pegs that brought about joint pain and which thereby improved the productivity three times. This saving of labour changed the scenario for all the weavers involved in the making of the Pochampally Ikat saree and fetched him the Padma Shree in 2017 that he so richly deserved.

The by-product of this tremendous effort

Already commercialized and available to weavers at economically affordable rates, it has improved lives for most of those involved in the weaving of the Pochampally ikat saree. Says Akubathhini Kavitha, a weaver from Warangal in Andhra Pradesh "We have four looms and it was very strenuous to provide the material for all the looms alone. Since we bought an ASU machine, I was relieved of hard work and also earning almost double than what I was earlier,"

L Chinzah, National Coordinator, Business Development & Micro Venture, National Innovation Foundation (NIF), talks of it as a tremendous path-breaking effort, that has revolutionized the working of the Pochampally saree community since there is no human involvement, the machine ensures that the weaver does not have the ill effects on health like shoulder pains or strained eye sight.

"The technology would be very helpful to augment the cause of uplifting employment efforts and health of women living in the margins."

NIF was established with the help of Department of Science and Technology, with the main goal of providing institutional support in scouting, spawning, sustaining and scaling up grassroots green innovations and helping their transition to self supporting activities.

And what are the thoughts of the Padma Shree awardee himself?

As per Mallesham the 250-watt Asu machine is 60 inches long, 40 inches wide and 50 inches high, powered by two motors. He has improvised on the machine’s design and brought in electronic components. “When I began the search for the solution, I began to learn the basics of computer programming through the help of friends, since I wanted to automate some processes. Even the effort to upgrade the device was seemingly unattainable. My education was only up to the X standard and my English language skills were highly limited. In fact I looked around Koti’s book market in Hyderabad for the right text books and a dictionary to make sense of the terminology.”

Today when he looks back he finds the effort has truly paid off. He regrets only that his innovation has been available for 15 years now but there are still at least 500 families in Nalgonda who still cannot afford to buy the Rs.25000 machine and continue to struggle with the old labour-intensive process.

In a long list of people that Mallesham is grateful to for their help in his upward journey he specially thanks Brigadier Ganeshan, who saw the machine at an innovations exhibition, promoted it at different platforms. One of the weavers from the Pochampally community Vanam BuchidAsu had commented to Ganehsan, “But for this machine, I would have given up weaving and shifted to the city for work.”

A bright future indeed!

Till date Mallesham has sold over 600 Asu machines. His modified loom currently requires 3000 leg and hand movements over a period of 2-3 days. And once he has tasted success after such a struggle, his types don’t rest on acquired laurels but surge ahead to explore what further can be done to simplify the process even further.

“I feel very happy when several women tell me that ASU machine has given a relief to them,” said Mallesham’s wife Suvarna, stating that her husband would continue his services for the betterment of weavers’community.

Expressing her happiness, Mallesham’s mother Laxmamma said, “When I advised my son not to enter into caste-based profession and explained pain in Asu work, my son has made it clear that he would continue in the profession and took efforts to prepare the Asu machine. After failing in his initial efforts, my son succeeded in inventing the time-saving machine.”

Mallesham now has dreams for his two daughters: Swetha, who is studying textile engineering in Salem, and Rupa, who he hopes will study fashion designing. “With education, my daughters should be able to do much more for the handloom sector than me and in lesser time.”

He received Amazing Indians Award from the hands of Prime Minister Narendra Modi and also got best innovation award.

Chintakindi Mallesham is one of a kind, a true innovator despite his humble background, proving another example that formal education while helpful is not the end-of-the-road for those deprived of it. In fact it just gets some of them even more determined to convert their loss into a substantial gain.

Perhaps over time, we shall see more such worthy examples of sons of the soil whose never-say-die attitude should see many in the Make in India list realized by Indians themselves.